Bisagras libres para puertas de ducha de vidrio a vidrio

The size, shape and surface finish can be customized upon your request. We have long-term strategic cooperative with well-known European shower company.

- Descripción

- Consulta

Descripción

| Número de modelo | CLP-L44 |

| Tipo | Bisagras libres para puertas de ducha de vidrio a vidrio |

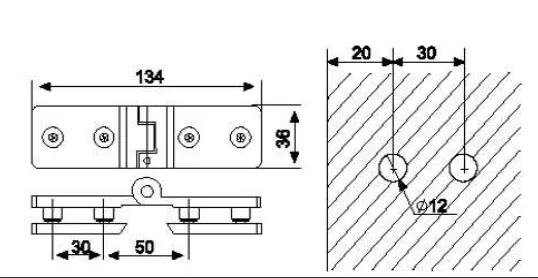

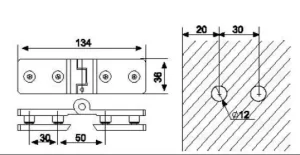

| Tamaño | 134*36milímetros |

| Espesor del vidrio | 6-12milímetros |

| Material | Latón forjado |

| Acabados | Cromo brillo/Dorado/Latón pulido/Níquel satinado/Negro mate,etc.. |

| Embalaje | embalaje individual |

| Unidad de peso | 459.5gramo |

| máx.. | 35kg/par |

48 horas de prueba de niebla salina, prueba de vida>100,000 tiempos de funcionamiento.

Dimension drawing of Glass to Glass Shower Door Free Hinges :

Brass has good corrosion resistance, wear resistance, high hardness, and is not prone to scratches.

Brass is divided into cast brass and forged brass. Casting is to melt the metal and then flow it into a cavity with a specific shape. After solidification, it forms a specific shape; forging is to heat the metal, but it is still solid, and then place it on a platform or in a mold of a specific shape, and use an air hammer to Such tools are forged into specific shapes. The production process of cast brass is simple, it can be produced in single pieces or in batches, and the price is relatively low; however, due to the production principle, there will inevitably be tiny pores, and the density is far less than that of forged brass. Forging can refine metal grains and has higher strength than castings, but the manufacturing cost of the mold is very high, and the price will be several times higher than casting brass. Moreover, in order to enhance corrosion resistance, brass must be coated, and the degree of fit between the coating and the copper alloy is an important indicator of quality.

The cost of forged brass is high, and the process requirements are high, so it is always used in high-end shower rooms.